Home | Rockwell | Brinell |

Micro | Durometer | Automatics | Accessories |

NB3010

Bench Brinell Hardness Testers (above

left)

Semi-Automatic

Operation. Cost-effective

Brinell tester uses deadweights with a pneumatic load system to apply and remove

the loads. Operates in all Brinell scales.

Download NB3010 Product Literature

AB7000 Bench Brinell Hardness Testers (above middle)

With automatic operation the 7000 Series Brinell Tester provides a lot of capability in a basic Brinell tester package. The tester uses a hydraulic load system delivered through a Belleville spring measurement system which accurately controls the load.

New literature in Production, please email Newage to request a copy when availableAB9000 Automatic Brinell System (above right)

Automatically Brinell Hardness Testers display the hardness result without using a Brinell scope. Used for high volume testing without operator influence. Uses a Rockwell-type method with a standard Brinell ball and test load to read out Brinell.

Download AB9000 Product Literature

Lab

B.O.S.S.?Automatic Brinell Scope

(above

far left)

B.O.S.S. Brinell Microscope Instantly measures Brinell impressions at

the click of a button. Reduces operator influence and speeds up testing. Many

digital functions for data storage and reporting.

Download

B.O.S.S. Product Literature

C-Clamp

Portable Hydraulic Brinell Tester (above

middle left)

A very versatile

portable Brinell tester that uses a hydraulic ram to apply the load. Accuracy

calculated to 1/2 of 1% of load.

Portable

Pin Brinell (above

middle right)

Lowest Cost Brinell Tester - the

Pin Brinell uses a calibrated shear pin to control the amount of load applied.

Consistent loading regardless of operator. Tests in 100 - 730 equivalent Brinell

range.

Download Pin Brinell Product

Literature

Brinell

Scopes (above

middle right)

Several models of Brinell scopes are available, ranging from a low

cost flashlight style unit to a advanced LED style, to the B.O.S.S. automatic

scanner

Download Brinell Scope Product Literature

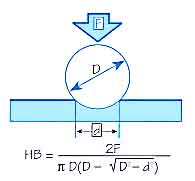

Widely used

on castings and forgings, the Brinell test method applies a predetermined test

force (F)

to a carbide ball

of fixed diameter (D) which is held for a predetermined time and then removed.

The

diameter (d) of the indentation width is measured twice - usually at right angles

to each other and averaged.

A formula (see diagram) or chart (see links) is then used to convert the averaged

measurements to a Brinell hardness number.

Brinell hardness calculation chart using a 10mm ball - Brinell

hardness calculation chart using a 5mm ball

Test forces

usually range from 500 to 3000 kilograms (occasionally down to 1kg in less frequently

used

tests). Carbide*

Brinell indenters are 10mm in diameter, although there are less frequently used

tests

with light loads and smaller diameter indenters (from 5mm to 1mm). Generally,

the Brinell tester load must be

held for 10 - 15 seconds although in practice shorter dwell times are often

used if it is known not to

influence the test result. The Brinell test measurement is typically done to

the nearest 0.05mm

using

a standard 20X Brinell scope. This measurement is subject to operator influence.

Also see the General Hardness Training Guide: Hardness Testers Part 1 Part 2 Part 3